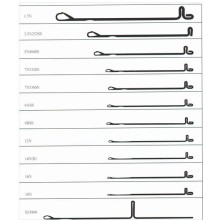

Dial Linking Needle

Basic Info

Model No.: all gauges

Product Description

Model NO.: all gauges Processing Type: Metal Processing Material: Metal Processing Trade: Processing with Material Supplied Customized: Non-Customized Gauge: 1.5, 3, 5, 7, 9, 10, 12, 14, 16 Gauges Needle Gauge: for 3,7,9,10,12,14,16 Gauges Machines Trademark: Stoll Origin: China Classification: Special Parts Match Machine: Knitting Machine Processing Level: Precision Finishing Certification: CE, ISO9001: 2000 Condition: New Delivery Time: Within 20-25 Days Needle Type: 3,5,7,9,10,12,14,16g Specification: ISO HS Code: 225300 It is the most general one needle applied to most kind of gauge Dial Linking Machine. The quality is assured and the price is best. Taizhou Tiansheng Knitting Machinery Co., Ltd. Combines research, design, production and selling in the knitting machine and is equipped with excellent equipment in China and it is one of the enterprises which have the knitting machine patent.

Contact us if you need more details on Linking Needles. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Needle、Linking Machine Needle. If these products fail to match your need, please contact us and we would like to provide relevant information.

| Gauge | 3-5-7G, 5G, 7G, 9G, 12G, 14G | |

| Weaving amplitude(inches) | 52 | |

| Knitting speed | Controlled by servo motor with 32 sections speed optional,Max 1.0m/s.Servo motor will use the precise back award control and link up the high speed operation ability of numeal signal processor(DSP),which control IGST to produce the accurate output electric current. | |

| Knitting system | single carriage,1 couples of cam system | |

| Knitting fuction | Knit,miss,tuck,transfer,pointel,intarsia,jacquard,apparent or hide shaping and other regular or irregular patterns. | |

| Racking | Controlled by servo motor racking within 4inches and with fine adjusting function. | |

| Probe alarm system | probe alarm safety device achieves up and down,side to side alarm function,breaking the current cross-field probe single plane swing detection function and achieve its features. | |

| Take down roller | programmed instruction,controlled by stepping motor,32 levels selection,adjustable area is:0-100. | |

| Encoder | Advanced encoder adopted. | |

| Transfer cam | the transfer cam is compose designed,can transfer.knit,tuck and miss alone to achieve high production efficiency. | |

| Stitch density | Controlled by stepping motor,32 section stitch selectable,adjustable scope supported by subdivision technology:0-720,the stitch of the knitwear can be accurately controlled. | |

| Yarn carrier | 1x6 sets of yarn carriers arranged in three left and right sides rails,switch yarn needle beds anywhere in the mouth. | |

| Protection system | When the machine is in motion the process of yarn breakage,joints,floats,rewind,number of pieces completed,move the bed did not return,hit the pin,the next program error,etc..automatic alarm,and a self-locking safety protection device. | |

| Control system | (1)adopt LCD touch screen and figure interface.input device:USB internal storage 1G,a great amount of design files can be stored at the same time and they can be fetched out for use at any time as per production reguirement. (2) monitoring menu: you can display various working parameters through the Chinese, English, Arabia language switching, and can be adjusted at any time when the machine is running, maximize the convenience of operation. (3) Free design system is visual and easy to understand and software upgraade free of charge. | |

| Network features | Through high speed Ethernet,the knitting data can transmission download and coexist. | |

| Power supply | single-phase 220V and 3-phase 380V,adopt advanced CMOS technology,having memorizing function at power shock stop. | |

| Dimensions | length x width x high: 2800x900x2000mm net weight: 700Kg. |

Contact us if you need more details on Linking Needles. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Needle、Linking Machine Needle. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Needles&accessories Of Computerised Flat Machine

Premium Related Products

Other Products

Hot Products

Knitting Needle Vo. 78.66/04Ceramic & Porcelain Vase for Gardening & Home DecorationRolling Column Style Six-Shuttle Circular LoomPlastic Lamination Machine for Non Woven & PP FabricHigh Speed Spunbond Nonwoven Fabric Extrusion MachineUpward Brand Stainless Steel Counterweight for SaleChina Upward Brand Customized Casting Iron Calibration Testing Weights Counterweight ManufacturerChina Hot Sale Non Woven Geotextile Production Line MachineMj153c Single Rip Saw Woodworking MachineUta710 Centralized Compressor 190cm Air Jet LoomUtm-320 Triaxial Automatic Wood Planer Sawing Machine Table SawChina Uw951 High Speed Water Jet Loom Weaving MachineWater Jet Loom (RFJW10)Terry Rapier Loom (RFTL60)Air Jet Loom (RFJA 20)High-Speed Rapier Loom (RFRL31)